curved copper roofing

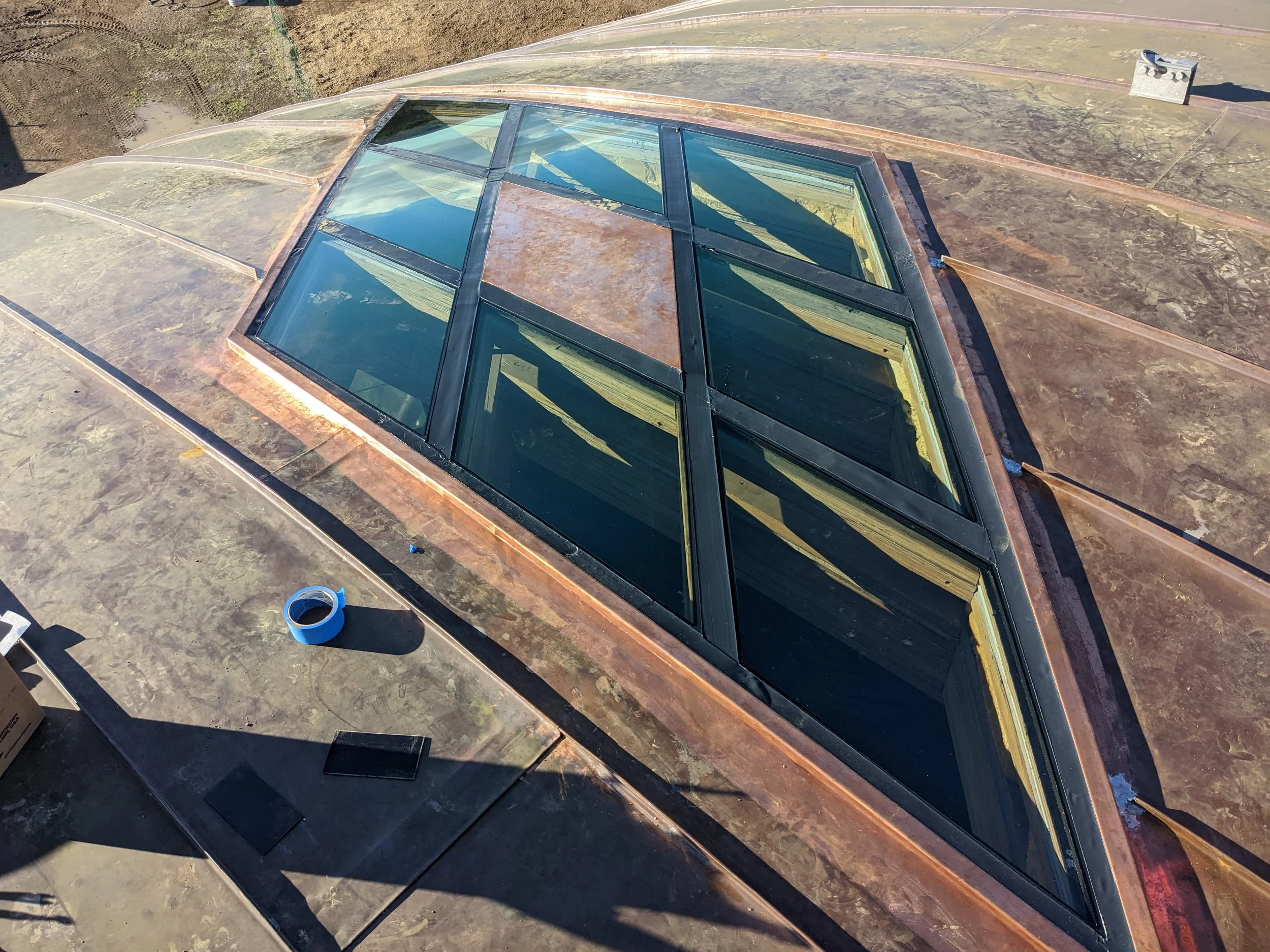

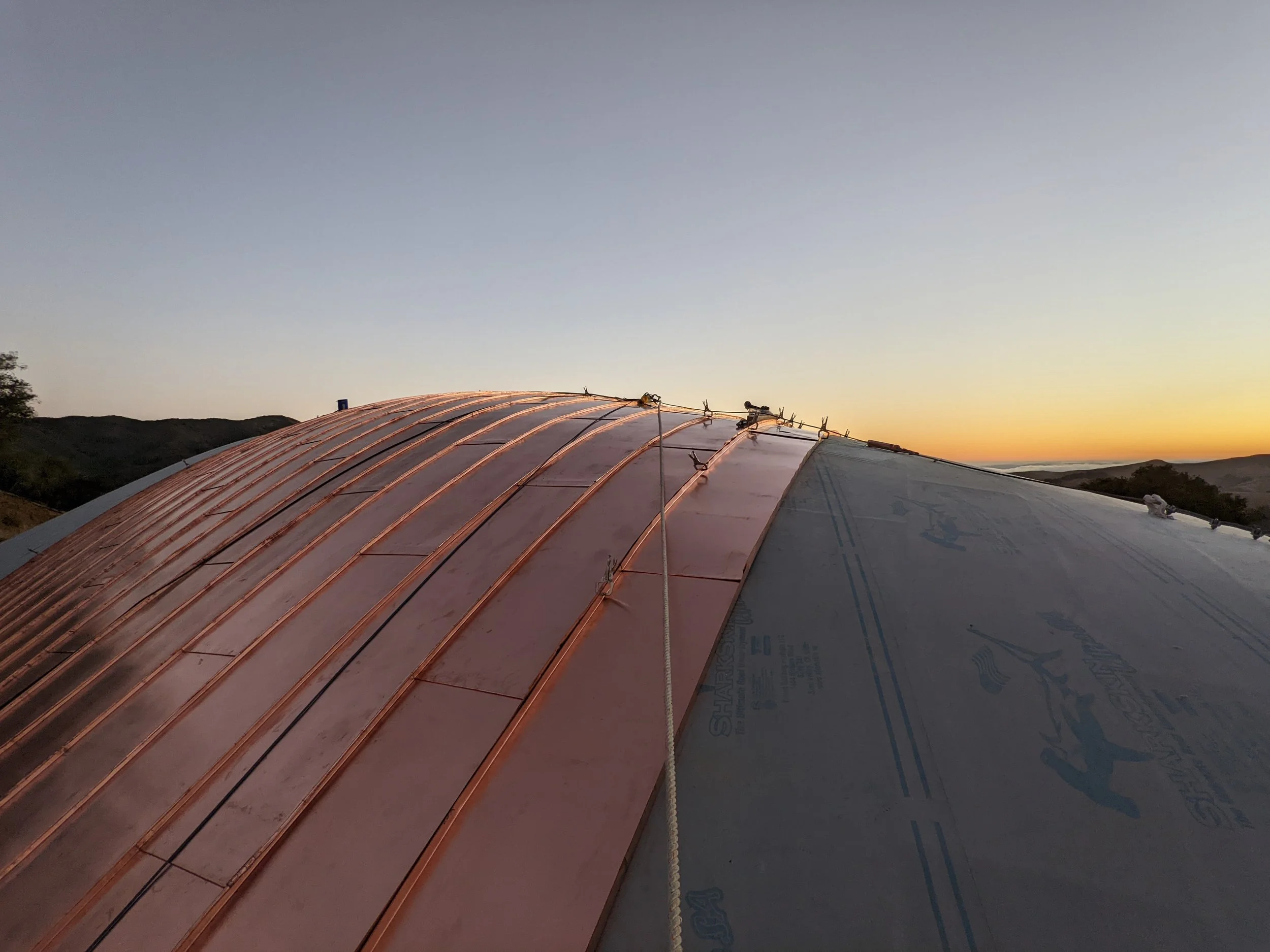

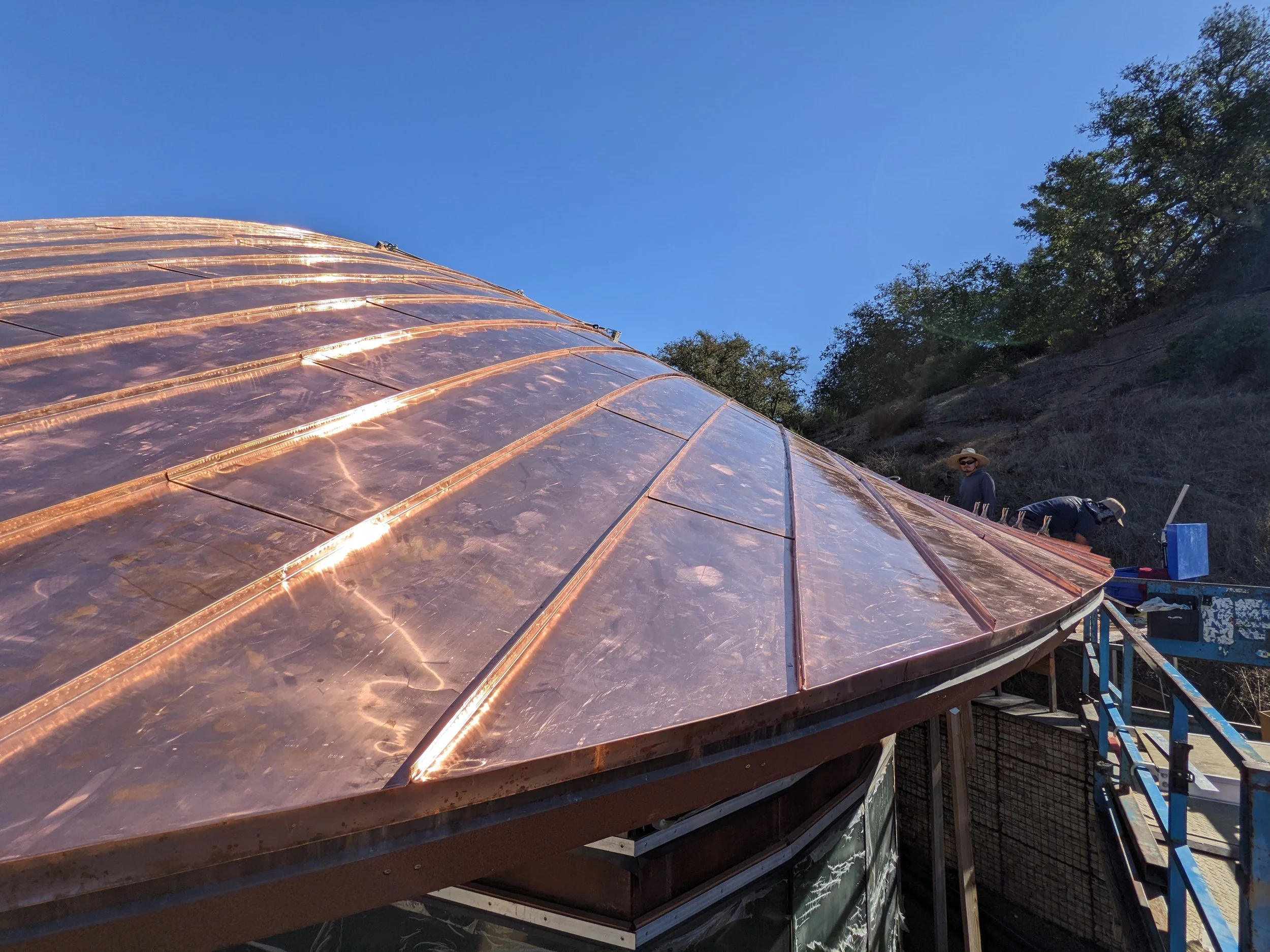

Over 500 unique copper panels were parametrically generated and fabricated on site to wrap the doubly curved roof surface over the timber gridshell. Each panel shape was precalculated using LiDAR scan data from the roof, allowing each piece to precisely register with the existing form.

Standing seams interlock across the surface, with panels cut and pre-curved on site and seamed in place during installation. Tight control over on-site variables and a fabrication process responsive to real-time conditions allowed the roof to be assembled with continuity and precision.

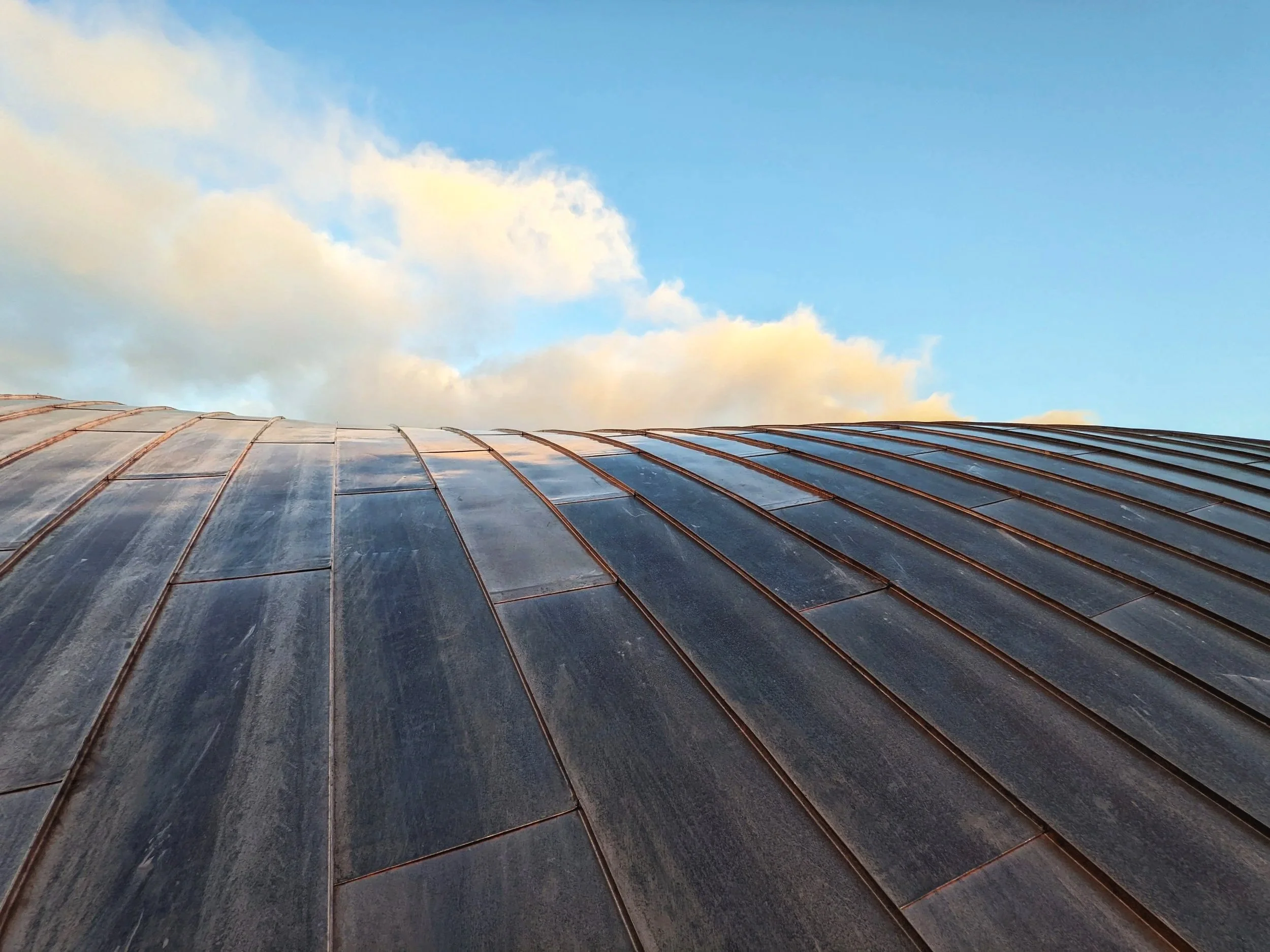

The resulting copper cladding is durable, non combustible, and designed to age gracefully over time.

materials: tempered copper

methods: parametric design & analysis, plasma cutting

status: complete