concrete balusters

This project explores the intersection of digital design, custom fabrication, and on-site casting. The balusters were designed to seamlessly extend the language of an adjacent freestanding concrete wall that was robotically milled, continuing its flowing geometry around a free-form curved opening in the mezzanine floor.

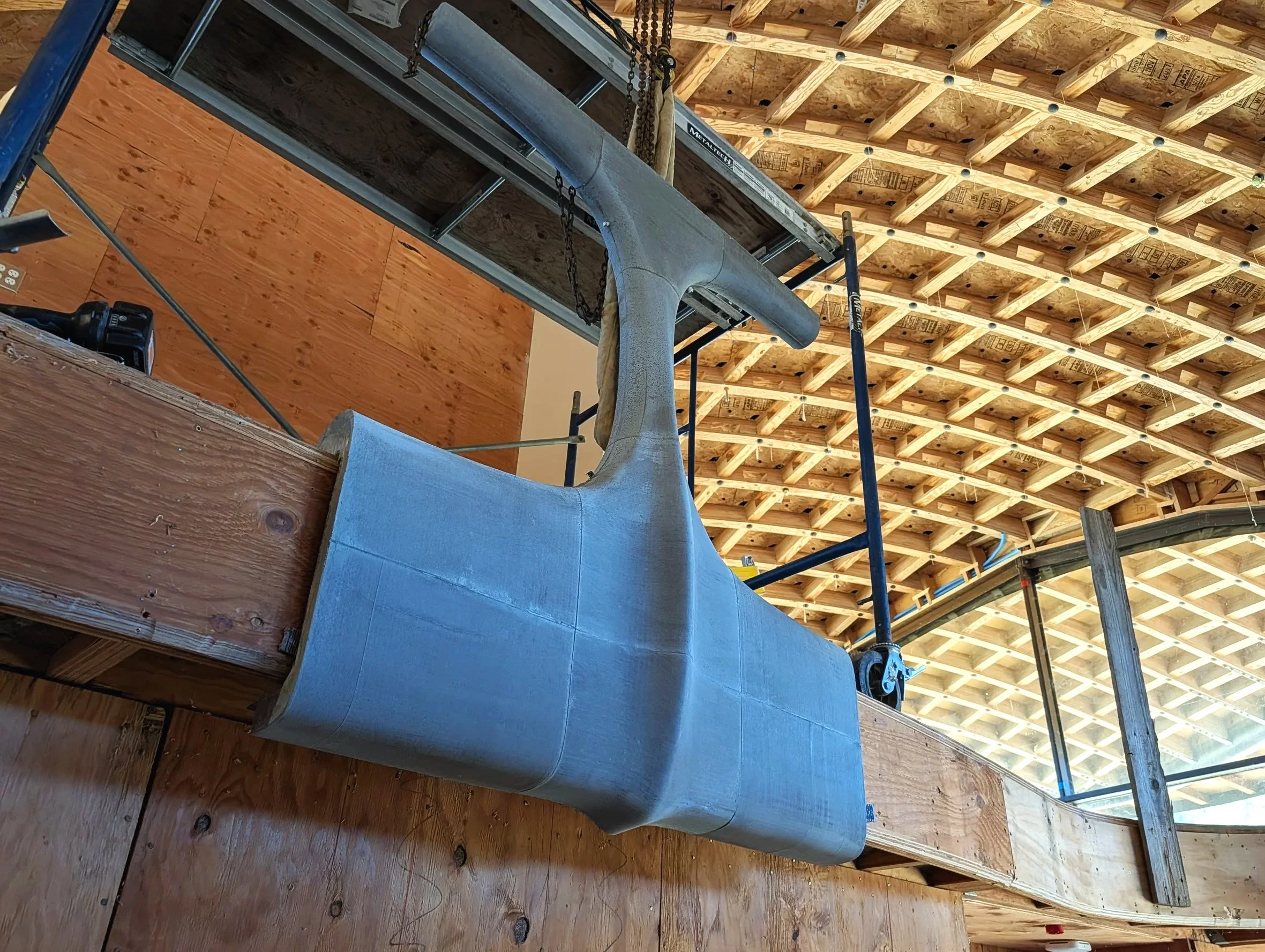

Molds were 3D printed, a steel support structure was welded, and the balusters were cast on site using high-strength concrete, then lifted into place for installation.

materials: concrete, steel, PLA, wood

methods: 3D printing NC milling, welding, concrete casting

status: in progress